可持续建筑围护结构中心已经建立,利用建筑结构产生能源。Here is a look at its ambitions and some of the key technologies under development

How can the building envelope be better used to actively capture, store and utilise energy? And how can pioneering research in this area be developed and applied commercially as an integral part of a building system?

These are two of the big questions being tackled by the Sustainable Building Envelope Centre (SBEC), which was set up last year by Tata Steel, the Welsh government and the Low Carbon Research Institute (LCRI), an organisation led by the Welsh School of Architecture at Cardiff University with involvement from five other Welsh universities.

Construction of the SBEC facility was funded by Tata Steel and is based at its Shotton works in north Wales. The centre, designed by the Welsh School of Architecture, reuses part of a production facility and consists of three floors of offices around an area for tests and exhibitions. It works as a proving ground for emerging building envelope technologies, whose performance will be evaluated over the initial three-year programme.

“We’re trying to create an end-to-end process for transferring knowledge from research institutes into the commercial world,” says director Daniel Pillai.

“It’s about transforming the role of the building fabric. Traditionally this has played a passive role in energy conservation. We believe it will become far more active in the future, capturing energy, storing it and using it. We’re trying to functionalise the surface of the roof and walls to capture as much of the solar energy that lands on it as possible.”

New building products

The centre is developing solar thermal and photovoltaic technologies that can generate renewable energy independently, in combination or as part of integrated energy systems that incorporate boost, storage, delivery and control elements.

在试验建筑产品的同时,我们希望开发设计方法和最佳实践指导,使设计师和规范人员能够将这些能源系统纳入他们的建筑中。”如果我们能找到一种储存夏季热量并在冬季释放的方法,我们就能让很多建筑自给自足,”皮莱说。

Research includes the application of coatings to a steel roof or wall surface to superimpose functions such as solar energy absorption. Transpired solar collectors, frameless photovoltaic, phase change material and embedded pipes in a steel floor deck slab have also been tested at SBEC.

If we find a way to store summer heat for release in winter, we can make buildings self-sufficient

Daniel Pillai

挑战在于使新技术成为建筑系统的一部分,并解决能源储存和释放问题,这是SBEC目前正在研究的问题。同时,TSC和无框光伏产品均已实现商业化。TSC系统将通过SBEC合作者及其延伸的供应链提供,Solon无框光伏板将以Solbond Integra的形式销售。两者都将于今年春天推出。

The products being tested at SBEC are steel-intensive and are being tested on a steel-framed building, although the technologies are expected to be more widely applicable throughout different building types.

SBEC’s findings will be disseminated through CPD. Given that buildings account for around 40% of all carbon emissions, the potential benefits of the SBEC work are “enormous”, according to professor Phil Jones, head of the Welsh School of Architecture and chair of the Low Carbon Research Institute.

The potential for using the envelope to collect energy is huge if you can integrate this function into the building design rather than have it as a bolt-on

Phil Jones

In this country we often come up with bright ideas but don’t necessarily take them to market. The SBEC work will take basic research on new products through to manufacture and demonstrate them in practice as part of a building system — all essential for getting new technologies into the market,” he says.

“The potential for using the envelope of the building to collect energy is huge if you can integrate this function into the building design rather than have it as a bolt-on. Then the envelope can perform two tasks — both envelope and generator.”

As well as installation at the SBEC building, the plan is to test the new technologies in eight buildings including housing, offices and factories in Wales so that their use can be monitored in real life situations. This £3 million project, announced last month is being backed by £1.8 million from the European Social Fund through the Welsh government.

www.sbec.eu.com

Transpired solar collectors

蒸发式太阳能集热器(TSCs)的工作原理是在集热器的外表面加热约5毫米厚的边界层,该边界层固定在一个南侧的高度。由通风机在空腔内产生的负空气压力将预先加热的边界层空气通过表面的微孔进入空腔。新的加热空气从空腔被送入建筑,或者直接作为通风空气,或者作为主供暖系统的预热器送入暖通空调系统。

A TSC system can meet up to 50% of space heating require-ments. They can be installed as an additional steel skin on to both new or existing walls (metal and non-metal) to create a cavity between the wall and the metal skin.

由塔塔钢铁(Tata steel)制造的预制彩色涂层棱镜钢(Colorcoat Prisma steel)增强了热吸收性能,吸收太阳的辐射能,加热金属表皮暴露一侧的空气边界层。

根据SBEC的说法,TSC系统与泵结合后,每年可以交付250k@h/m2,并在三到七年内收回成本。

SBEC大楼现正试用两种类型的TSC。在朝南的墙壁上,无烟煤梯形剖面收集器将大量预先加热的通风空气输送到原型舱中,减少了对不可再生热源的需求。

Linden Green太阳能收集器——一种为商业应用而设计的盒式立面系统——将预热的空气输送到办公区域的空气处理单元。在必要时,可以通过空气源热泵来提高这一点。

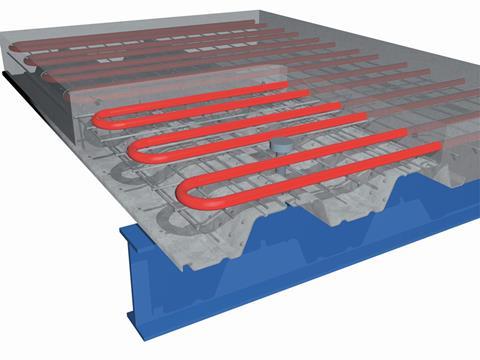

Thermo active floor

Pipes embedded in the concrete/ steel floor deck enable the slab to be chilled by circulating cold water, absorbing thermal gains during the day and storing the captured heat so that it can be released at night.

For heating, water warmed by heat pumps or a transpired solar collector can heat the radiant floor slab — requiring temperatures of only 30-35°C.

At the SBEC, a radiant composite floor deck — ComFlor 60 — has been installed in the first-floor offices and is connected to the building management system to use renewable solar-heated TSC air on a sunny day and an energy-efficient heat pump on a dull day or at night time.

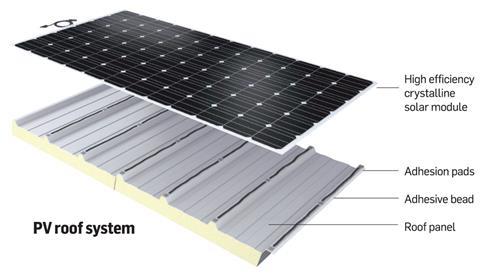

Lightweight photovoltaics

The Sustainable Building Envelope Centre is trialling a frameless lightweight PV system on both its own roof and that of the newly refurbished Deeside Leisure Centre.

The panels have a weight of less than 10kg/m2 and use 3.2mm transparent toughened safety glass. This uses 42 high-performance Solon Solbond crystalline PV panels covering an area of 84m2.

这些模块每年能够产生9.69兆瓦时的电力,并通过一种先进的工业粘合剂直接粘接在屋顶表面。适用于静载能力较低且不需要加固的屋面。

锚定方法依赖于晶体太阳能模块下方稳定的彩色涂层Prisma预制钢面板。

PV accelerator

This £11 million development project is researching the application of dye-sensitised solar cell “paint” to a steel substrate to generate electricity.

The project — a partnership between Tata Steel and Dyesol — is expected to be prototyped at SBEC within the next year. The ultimate aim is to incorporate this energy-generating technology within the fabric of the building, eliminating the need for a separate element.

The project is a development of technology patented in Switzerland some years ago and arose from Tata Steel’s research into anti-weathering pigments. According to Rodney Rice, Tata Steel’s business development manager — photovoltaics, the accelerator is a series of coated and printed layers that build up the structure of a PV cell.

This active material is just 50 microns thick (each micron is one-thousandth of a millimetre). It is sandwiched between a steel base and a polymer packaging material.

“它的潜在好处是灵活和轻量化,因此可以应用于目前无法承受光伏板负荷的建筑。

It also has implications for appearance because it is the roof rather than something bolted onto the roof, so would give freedom and flexibility,” says Rice. The product is expected to be ready for commercialisation in three to five years’ time.

In a separate project, other new coatings for steel and other substrates that can generate power are being developed in the £20 million Specific project at Baglan in south Wales.

该创新中心由斯旺西大学领导,塔塔钢铁公司作为主要的工业合作伙伴,旨在开发功能性涂层钢和玻璃产品,将建筑物的屋顶和墙壁转化为产生、存储和释放能量的表面。

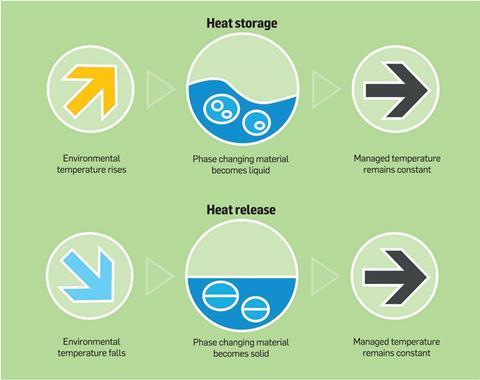

Phase change material

SBEC is testing the application of phase change material (PCM) as an addition to the thermal mass of the building.

微胶囊石蜡在24°C融化,并被纳入复合楼板。当建筑物过热时,它会融化并吸收多余的热量,从固体变成液体。当温度降到规定的水平以下,液体又变成固体时,热量就会释放出来。

This can be used in floors, walls or ceilings to capture, store or buffer thermal energy and enable a constant room temperature to be maintained.

SBEC的PCM位于一楼会议室之上,是塔塔钢铁(Tata Steel)的ComFlor 60 Active层甲板。这采用了BASF的微米PCM的形式,在钢甲板上的混凝土混合物中。

Postscript

1Readers' comment